Baincut LSS Plus

Metallography Equipment - Baincut LSS Plus

Precision cut off machine

PRODUCT CODE: LSS003A

- Cutting capacity up to 50 mm dia

- Cut-off wheel dia 4" to 7"

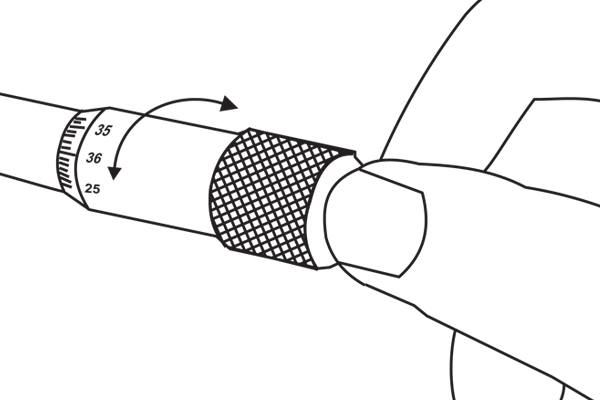

- Positioning accuracy 0.01 mm

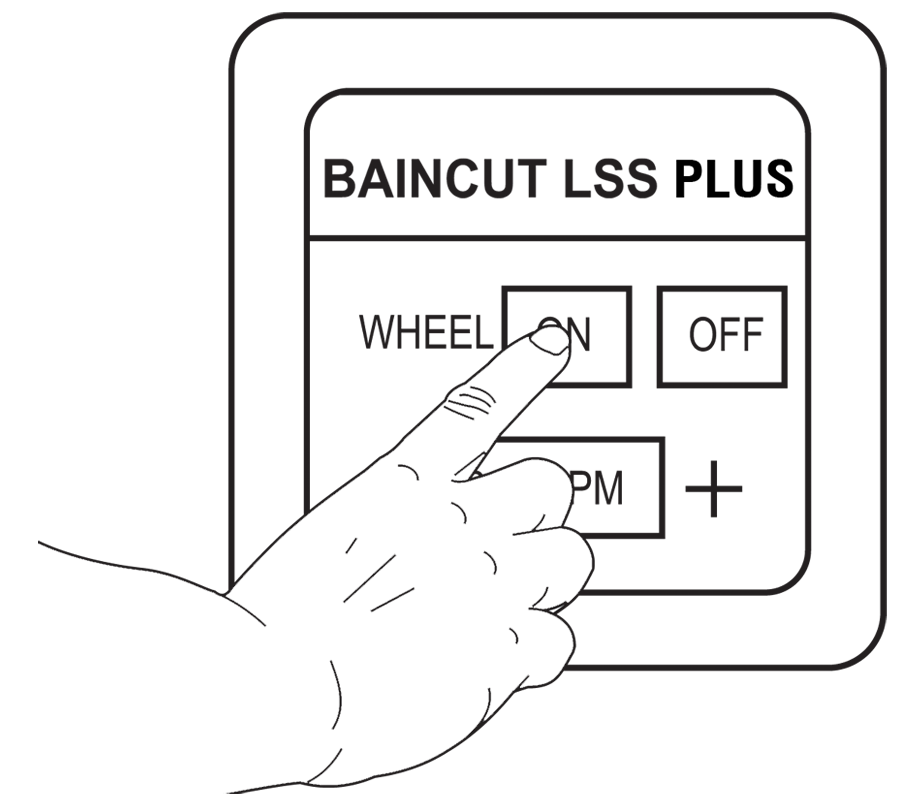

- Color touch screen HMI

- Arbor size-12.7mm

- Spindle speed 60 - 1000 rpm

- Machine size: 650mm X 550mm X 420mm

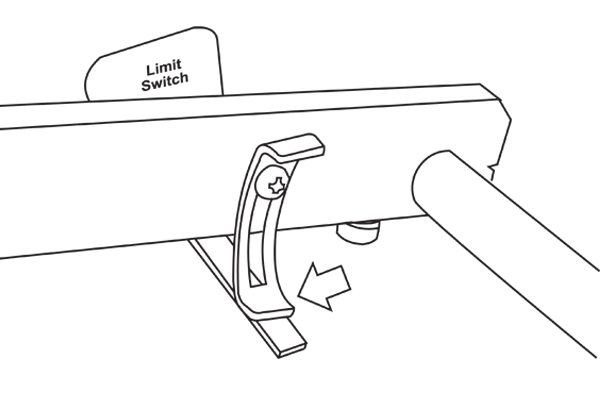

A precision section saw designed for cutting all types of materials with ease. Low-Speed Precision cutter is applicable to accurate cutting of hard materials, especially to high-value fragile artificial crystal. The Spindle has high accuracy of operation, the horizontal feed position of the processed work piece can slightly be adjusted, and the machine can be power-off automatically after cutting is finished.

Key Features

Optional

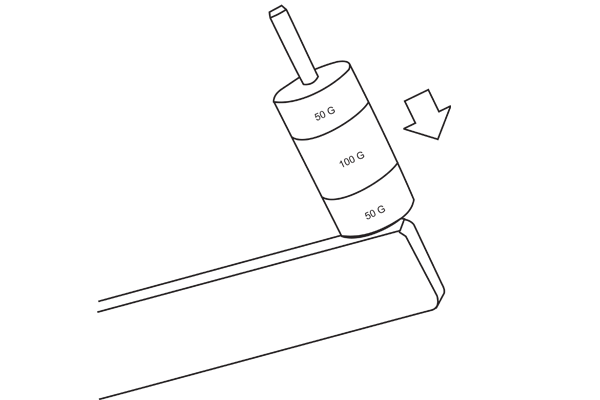

Work Holding Device

Height Adjustment Block (Imported)

Consumables

Cutoff Wheel

Size (mm)

Uses

Application

HRC

EU515L

125 X 12.7 X 0.4

Low Concentration Blade

Ceramics, Carbides, Boron Composites, Glass, Refractory

EU620L

150 X 12.7 X 0.5

Low Concentration Blade

Ceramics, Carbides, Boron Composites, Glass, Refractory (above 60HRC)

CWD002

150 X 31.75 X 1

Low Concentration Blade

Alumina ceramic, Silicon-Nitride ceramic, glass, copper, and iron, ruby, Quartz, Silica

EU515H

125 X 12.7 X 0.4

HIgh Concentration Blade

Polymers, PC Boards, Titanium, Thermal Spray Coating, Metal Matrix Composite

EU620H

150 X 12.7 X 0.5

HIgh Concentration Blade

Polymers, PC Boards, Titanium, Thermal Spray Coating, Metal Matrix Composite

EU515C

125 X 12.7 X 0.5

CBN Blade

High-speed steels, Inconel, Stellite, Iron and Cobalt based alloys, Nickel based Super alloys, Lead base alloys, Titanium alloys and Stainless Steels

EU620C

150 X 12.7 X 0.5

CBN Blade

High-speed steels, Inconel, Stellite, Iron and Cobalt based alloys, Nickel based Super alloys, Lead base alloys, Titanium alloys and Stainless Steels

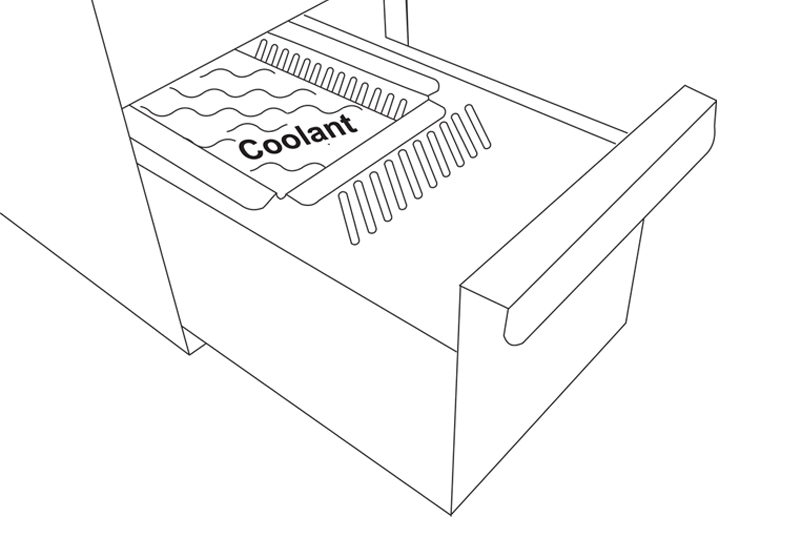

DB101

Isomet Oil

Coolant for burn free cutting

Oil-based coolant which can efficiently reduce the Cycle time of Cutting. Used with precision cutting saws. Do Not Mix with Water